Lush. No notes.

SS-30M

Friday, November 25, 2022

Tuesday, June 21, 2022

Wakey-wakey! - Rick Wakeman's SS-30s

Here's Rick - Spot the SS-30!

|

| Rick Wakeman - (Butler/Daily Express/Hulton Archive/Getty) |

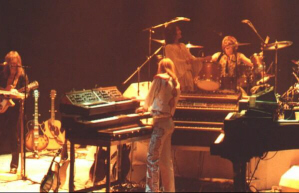

Tourmato 1978-79

.jpg) |

| Tormato - 1978 |

It was then time to embark on a 101 date US and UK tour running from 1978 to ‘79, Tourmato. On a giant revolving stage. Obviously Rick would need more than three keyboards, so he added a couple of Minimoogs (naturally) a grand piano (of course), Prophet 5 (nice) and more. At some point in the 10-month tour he added two SS-30s. He already had a Yamaha CP-30 electric piano (also pictured above) so I guess he was well disposed towards this range.

|

| Yes live before - CP-30, space echos, Birotron, x2 Minimoog |

|

| Yes Live after - CP-30, x2 SS-30 and x2 Minimoogs |

You can hear the SS-30 towards the end of Circus of Heaven, and see Rick playing it in the footage from June 1979 at The Spectrum in Philadelphia.

Why have two? If you’re playing to thousands of people every night the pressure to not only play well but also handle all the technicalities of a rock gig are quite daunting. Add the fact that you have 101 such concerts to endure then you would want to make things easy for yourself.

Looking at earlier footage he seems to be using a similar rig to what you can see here in an live set-up from a several earlier. On the left side he placed two Minimoogs on top of a dual-manual Mellotron. This was a custom built instrument with two trons in one cabinet.

|

| Rick Wakeman (around 1974) |

|

| Tourmato 1979 in motion |

Rhapsodies - 1978-79

The introduction to the stage rig of the SS-30s seems to fall into the period when Rick recorded his next solo album, Rhapsodies. Was the SS-30 used in the recording though?

Tourmato took a break between November ‘78 and April ‘79 and based on footage from 1978 and the Philadelphia show in a June ‘79 I guess the SS-30s were added during the break and therefore around when the album was being recorded.

|

| Rhapsodies - 1979 |

The assumed SS-30 is used extensively on this album and is quite prominent on many tracks. For example on March Of The Gladiators it is heard from the off and through-out. At times it may be two SS-30s being played together. Sea Horses has a rather typical use of synth strings, creating a pad or bed to lift the mood. The Flasher is a standout demostration of strings synth, playing a chunky riff at the outset, then arperggios then swells of chords. Later in the piece a melody is played on what must be the SS-30. Swan Lager (a reggae version of Swan Lake. What?) has some very, very string synths style pads. In seems rick was enjoying the opportunities offered by the stringer and putting his Mellotron/Biotron days behind him.

1980 Tour

In 1980 The English Rick, sorry, Rock Ensemble was reformed by Wakeman and taken out on tour. You can see he has kept the same setup as used on Tourmato. What’s better now is you can really see the SS-30s in use much more clearly in this concert recorded by Swedish TV.

The tour setlist includes a couple of numbers from Rhapsodies, but I don't think any are included in this concert. Nonetheless the SS-30 is used thoughout.

Another point is that he is playing chords

on the SS-30 with his left hand and soloing on the Minimoog with his

right, as you'd expect. Crucially though, he switches postion and

sometimes uses the pair on the left and sometimes the pair on the right.

So, depending on which Minimoog he wants to solo on he uses the SS-30

underneath. Even if you can effortlessly play with two hands crossing

one arm over and under the other is difficult.

1984 -1981

The following year Rick recorded and released 1984 and took it onstage at the Hammersmith Odeon, seemingly sponsored by Korg!

|

| Some of Wakemans's late arriving Korgs ready for live performances of 1984, in 1981 |

As Rick explained to Music Radar:

I developed a great relationship with Korg during the ‘70s. Back then, there was no such thing as sponsorship. If I wanted a synth, I had to buy it. But the Japanese companies were the first to realise the value of artist promotion. If people saw me playing a Korg synth and they liked the sound, they were going to buy one.“I was flown out to Japan by the big boss of Korg, Kato San. What an amazing man! He said, ‘Rick, I want you to try all our keyboards. Take them on tour with you’.

Seemingly he had hoped for the Korg consignment to come through ready for the recording of the 1984 album in early 1981, but they weren’t delivered in time. Instead he had to settle for whatever he had lying around and could beg and borrow. The old RMI with new Prophet 10 and Synclavier instead. Never mind, eh?

|

| 1984 - 1981 |

The sleeve notes for 1984 are more forthcoming about Rick’s gear than Rhapsodies and on Forgotten Memories, alongside Prohets 5 and 10, acoustic piano and Minimoog is listed 'String Machine'. Which one though, Rick?

Thanks to muzines there’s an interview from the time, where he has this to say.

I've used the Yamaha string machine and I've also made up my own strings using a Prophet.

To get my electronic string sound, I put down a basic string machine track on tape. I then add Harmoniser treatment to detune and chorus it further. I then use the Yamaha electric piano with all the attacks on full and all its sustain off and put this on the front for the attack. I put a strong echo on as it's mixed on to another track. Finally, I bring the echo of the string machine up front, cutting off the echo at the end so it's a more natural sound.

Then, referring to War Game

It ends with an upward portamento on synth over sustained Yamaha string machine sound.http://www.muzines.co.uk/articles/rick-wakeman-in-1984/3626

References

- http://www.progarchives.com/forum/forum_posts.asp?TID=98771

- https://www.facebook.com/YesWakemanMellotron/

- https://yesmusicpodcast.com/tag/mellotron/

- http://www.metal-discovery.com/Interviews/rickwakeman_interview_2010_pt3.htm

- http://www.muzines.co.uk/articles/rick-wakeman-in-1984/3626

- https://www.musicradar.com/news/rick-wakeman-on-his-top-5-synths-i-suddenly-had-an-instrument-that-could-give-the-guitar-a-run-for-its-money

Friday, June 17, 2022

Oli Freke, Synthesizer Evolution & SynthTrax

Oli Freke has started a Wiki site deicated to identifying which synths were used on what track.

It's called SynthTrax and of course I have been over and editted the SS-30 entry - who else could do it?

Who is Oli Freke? When he's not managing BBC's iPlayer he is a writer and musician with a lomg history and interest in synths. See here: https://www.linkedin.com/in/olifreke/

.jpg/300px-YAMAHA_SS-30_(1977).jpg) |

| Yamaha SS-30 - Oli Freke - SynthTrax website |

Synthesizer Evolution

Actually, I was meaning to post about Oli's book Synthesizer Evolution since I got it last year. The book is a kind of directory of synths, drum machines and samplers and covers the period 1963 -1995. Its particular charm comes from the line drawings of each piece of gear listed. Of course the SS-30 is included and there is the lovely drawing of it above.

The book was inspired by posters Oli created showing the evolution of synths.

It doesn't go into great detail on each synth. Even the big beasts get just a couple of lines beyond the basic description of what type of synth it is. Instead most of the text is about the type of gear in each section: synth, drum machine; sampler, and the major companies, like Yamaha.

It's a really great book for the likes of us and there are lot of really obscure machines in there that will send you off in search of them online, as well as reminders of how the market evolved from analogue to digital and then back again. Which is the subtitle of the book!

SynthTrax

SynthTrax was started by Oli early in 2022 and is described best by him on his blog post about here. In summary though, he's trying to create a place where verifed uses of synths on tracks can be collated and the usual heresay and specualtion is left behind. As I have spent time doing that for the SS-30, it makes good sense for me to share what I've researched for this site with that noble endevour.

Each synth on SynthTrax should have two pages. There's the article page with general info about the synth and a section on associated artists. For exmaple Ultravox's heavy use of the SS-30 is well known. Here is the SS-30 page https://synthtrax.net/index.php/Yamaha_SS-30_Article_Page

Then the main effort goes into the track (or song) list. The SS-30 list is here: https://synthtrax.net/index.php/Yamaha_SS-30_Song_List

As I type this I have mostly completed the Article page and there is just one entry on the Song List page for the SS-30 (Ultravox - Vienna).

Friday, June 10, 2022

An SS-30 repaired - MIDI Installed - demo

Here are a pair of videos from Alexey Taber titled "YAMAHA SS30 - installing MIDI" parts 1 and 2. Although no specfic details are provided, the machine has been repaired and then had MIDI installed

There's no explaination about the MIDI interface or repairs, just a demo of SS-30 in operation. Sounds like it's in good condition though.

Thursday, November 11, 2021

Synth Wizards Episode 11: String Machine Madness!

Sadly no SS-30 in this otherwise fairly comprehensive film about string machines, but then the SS-30 was never sold in the US. Yes, it says the SK-20 was the first Yamaha stringer too, but you have to forgive them.

It's lots of fun - despite this carping - and I haven't seen anything else cover as much ground in video form with actual examples of so many different instruments.

Edit. The SS-30 has a cameo in this Syntaur film about the DX1!

Wednesday, November 10, 2021

Tuesday, November 02, 2021

SD 80'81 - Tuning

This post has been moved to https://norgatronics.blogspot.com/2021/11/sd-8081-tuning.html